AGES ‘unit in Kulltorp saw the benefits of signing an agreement with Jernbro regarding preventive maintenance (PM). Ensuring the implementation of PM while being able to put all the energy into its main service, die casting of aluminum, were two of them.

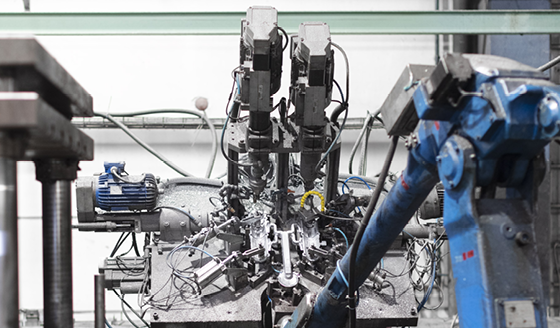

In April, AGES and Jernbro entered into an agreement which means that Jernbro takes full responsibility for the planning, implementation and documentation of preventive maintenance for AGES foundry machines, processing machines and tumbling equipment. AGES Kulltorp delivers refined die castings in aluminum where post-processing in 4-axis processing machines, tumbling, blasting and surface treatment are included.

– The purpose of the agreement is for AGES to be able to release the maintenance and feel secure in the fact that we now manage and optimize all PM. It’s also our responsibility to propose opportunities for improvement to secure and increase the operational reliability of the equipment. Another advantage for AGES is that they now have one supplier to turn to instead of several, explains Anders Gustafsson, Jernbro regional sales southwest.

AGES has been an important customer for Jernbro since 2015. Over the years, it’s primarily their press foundry that Jernbro has carried out preventive maintenance and emergency repairs on. When AGES needed help with moving three foundry cells from Solna to Kulltorp, the assignment went to Jernbro for dismantling, moving and installation. Furthermore, during periods when AGES has been overloaded with work, Jernbro has supported them with maintenance mechanics, electricians and engineers.

Anders explains the background to the agreement:

– The reason why we now have signed an in-depth cooperation agreement, is that we over the years have done a good job that AGES has been satisfied with. We have a high level of expertise in die casting and machining, and since we have a wide range of industrial services, it’s sufficient that they turn to us to solve both ongoing work and any challenges. We have simply set up and provided the services that AGES has sought. In addition, we have offered order in the documentation.

An important part of the work is the documentation. The fact that the protocols regarding preventive maintenance are up to date and that measures have been completed in order to be able to demonstrate that the maintenance is carried out, is of primary importance to both AGES themselves and their customers in automotive, industry, construction and aids.

– It feels especially good to be able to provide AGES with our expertise and our methods as part of their ambition to create increased operational reliability, since they are a close customer with whom we have a constructive relationship, Anders concludes.