WELDED CONSTRUCTIONS FOR DEMANDING ENVIRONMENTS

Quality, function, performance and safety permeate our design and manufacturing processes of pressure-bearing devices and steel building structures as well as lifting equipment. Our cutting-edge expertise allows us to design, manufacture, control, test and document advanced welded constructions in those in carbon steel materials and stainless steel material combinations that meet the most comprehensive requirements specifications and demanding environments from our customers.

COMPANY CERTIFICATIONS

We are certified in third part by accredited certification bodies for welding with associated processes according to SS-EN ISO 3834–2: 2005 and for steel constructions and load-bearing constructions according to SS-EN 1090–1: 2009 and FPC systems (Factory Production Control) in design class EXC 1-3.

- We CE mark load-bearing components and steel building structures according to SS-EN 1090–1 EXC 1-3

- We CE mark pressure-bearing devices according to PED AFS 2016: 1 (2014/68/EU) Module G

- We CE mark lifting equipment and lifting devices according to SS-EN 13155 and MD 2006/42/EC

Our mission

Regardless of whether it concerns the design or manufacture of pipelines, pressure vessels, mechanical equipment, pipe support structures, lifting devices or load-bearing steel structures, we can perform deliveries or parts of deliveries.

Welded constructions in complex materials

Materials we manufacture in are

- Unalloyed carbon steel

- Low alloy carbon steel

- Austenitic stainless steel

- Austenitic-ferritic (Duplex and Super Duplex)

- Stainless steel

- Super austenitic stainless steel

- Heat-resistant steels

- Aluminum

- Aluminum alloys

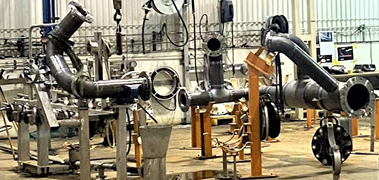

Our workshop for stainless steel

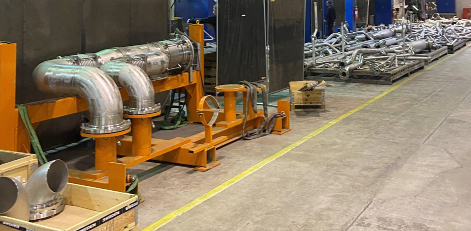

Our pressure test for carbon steel

Welding work in our workshop

Our workshop for carbon steel

Certifications, methods, control, processes, qualification

List of below is found in this pdf.

- Pressure equipment – Regulations and standards

- Eurocode 3 – Regulations and standards

- ASME BPVC – Codes and standards

- NORSOK – Regulations and standards

- Manufacturing product codes and standards

- NDT Personnel – Qualifications and certifications

- Non-destructive testing – Methods

- Destructive testing – Mehods

- Weld metal inspection

- Weld processes

- Welding Procedure Qualification