For you and our other customers in the industry, there are major challenges in ensuring the operation of the machine park and in particular for older equipment:

1. There’s no supply of spare parts

2. Many actors and complex systems

3. Difficult to find competences regarding older systems

Our spindle service can in many cases solve the challenges since:

– We can repair, renovate and test drive different spindles

– We have unique opportunities to renovate complicated spindles

This combination means that we can offer solutions that ensure long-term machine operation.

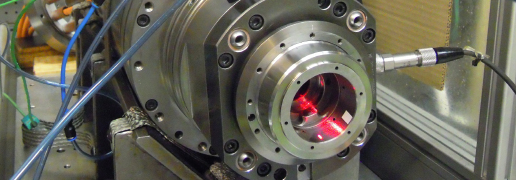

The film shows a test run of a belt-driven spindle

We perform repairs and renovations of

– Motor spindles

– Belt driven spindles

– Drill boxes

– Powered tools

– Grinding of ISO cones at your site

Test run and balancing of a spindle motor

We offer everything from disassembly to test driving and balancing

With our machinery and appropriate equipment, we can:

- disassemble complicated spindles

- troubleshoot

- renovate defective parts

- test drive and balance after renovation

We can also add bearing kits to our warehouse. It streamlines the renovation work for recurring jobs. It also acts as an insurance that minimizes the consequences of any breakdowns.

Quality and experience

Our high competence and long experience of motor spindles means that we can renovate your important milling and grinding spindles with high quality. The condition of the spindles is often decisive for the quality outcome of the end product. With great knowledge and high accuracy, we guarantee a good result.

Guidance

Tool spindles are complicated and require high precision to function satisfying. With our broad experience, we are helpful in solving your specific problems.

Measurement of a spindle

Component service at our workshop or at your facility

You usually send the component to us, and we carry out the work in our own specially equipped workshop in Avesta and Skövde. But if you need service at your facility, we will of course, come to you.

In Skövde, the focus is on high-precision spindles, primarily for the engineering and woodworking industries. In Avesta, we repair larger spindles that are primarily used in steel and sawmills.

Components for repair should be delivered to:

Jernbro Industrial Services AB

Strängslundsvägen 11

549 65 Skövde

or

Jernbro Industrial Services AB

Källhagsgatan 18

774 35 Avesta