We have many years of experience in cutting machining and renovating complex details. In the workshops there are several machines and technically knowledgeable personnel. We offer many machining services and appreciate challenges where we can leverage our problem-solving ability.

We obtain details with high requirements and tight tolerances through milling, turning, drilling, grinding, water cutting, measurement and more. Our competent team ensures that the final product meets the customer’s requirements. To our assistance we also have our measuring arm with probe measurement as well as 3D scanning which, among other things, enables reverse engineering, analysis and investigation of defective equipment.

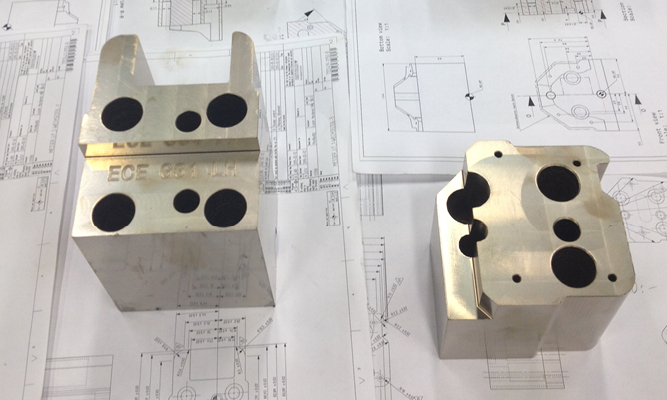

We carry out machining in steel, stainless steel, bearing metal, aluminum and plastic.

We offer specialist services in machining in our workshops in Skultuna, Avesta, Sandviken and Kiruna.

See our machine list >

Milling

We have more than 15 CNC milling machines as well as many manuals with which we can handle pieces that weigh up to 10 tonnes and details with a maximum length of 6 m and process 4-axis simultaneously. Products we mill are for example bearing housings, clutches, axles and brake discs.

Milling machine with round table

Milling

Lathing

In the workshops we have more than 20 CNC lathes and several manual lathes. We can lathe pieces up to 15 tonnes, detail lengths of maximum 8 m and 2.8 m in diameter as well as processing 5-axis simultaneously. Products that we lathes are for example, shafts, bushes, gears, lining drums, clutches and brake discs.

CNC lathe

Boring

With our 5 CNC drill mills and our manual ones we can handle pieces that weigh up to 25 tonnes, details up to 6 m long and 2.5 m high and processing 4-axis simultaneously. Gearboxes, feeder screws, motors, flanges, frames, gears, clutches and brake discs are examples of products that we can handle.

Boring

Grinding

We have more than 15 pieces of grinding machines in the form of flat, round, roller, sharp and holes, some of which are CNC controlled. The machines can grind pieces that weigh as much as 15 tonnes and detail lengths of up to 5 m and 0.9 m in diameter. Products we grind include, for example, rollers, scissors, shims, tools, punches and spacers. In addition to previously mentioned materials, we also grind rubber.

CNC grinding

Repair of hardened punching and pressing tools

We can repair your hardened punching and pressing tools. This means that we weld on the right material which then is processed in our machinery and which is eventually cured. We receive tools by mail or courier.

Water cutting

With abrasive water cutting we can figure out complicated shapes in virtually all existing materials, such as steel, stainless steel, titanium, ceramics and composite materials. During water cutting, no stresses or micro cracking are formed in the material and the quality of the pre-cut edges is high. The 0.2-1.5 mm wide cutting beam also gives minimal waste of material.

Abrasive water cutting

Measuring arm with 3D scanner

Our measuring arm has a range of 1.35 m and can handle a measuring range of 2.7 m. We can analyze details and collect measurement data to create a digital three-dimensional model with the arm . The 3D model is used to analyze deviations or to construct new components. The arm’s measuring probe is advantageously used to check manufactured details. The measuring arm is portable and can be mounted on a stand or with a magnetic foot in our customers’ facilities.

Measuring arm with 3D scanner