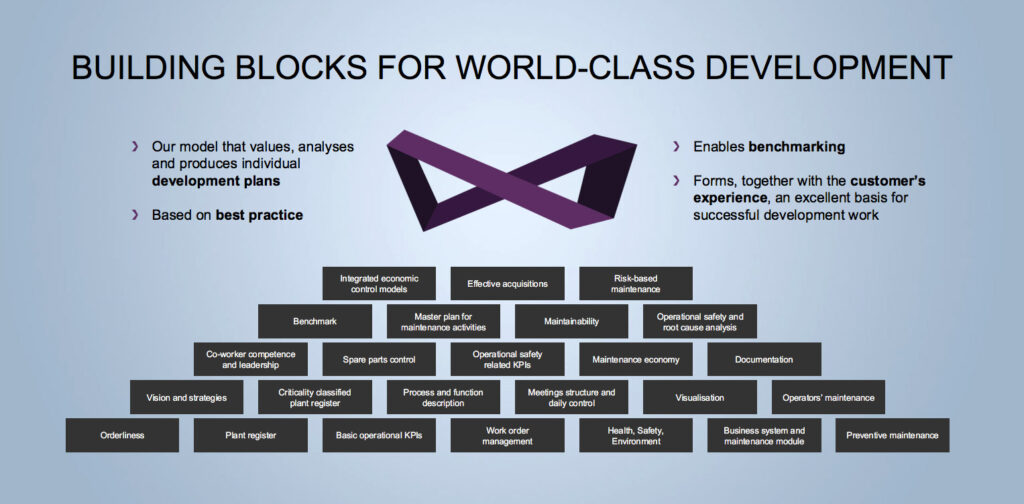

In order to develop your maintenance and be able to offer you world-class maintenance, our maintenance engineers work according to the Jernbro Maintenance Way (JMW). Using the method, we identify not only what needs to be done, but also how and why.

We start by evaluating and analyzing your maintenance operations to find out which efforts give the best results and ensure the quality of everything in templates, processes and routines.

With the help of the results, goals, challenges, resources and best practice, we develop individual and long-term development plans. By following these, maintenance costs will decrease and operational reliability will increase, for example.

We evaluate the business according to a standardized model and measure development over time. This allows us to compare different maintenance activities. JMW will thus also be a tool for benchmarking.

Jernbro Maintenance Way is a proven method, which is largely based on concepts such as Lean and TPM, but is packaged and adapted to suit maintenance operations. The method is illustrated in the form of a pyramid, which consists of a number of blocks. Each block represents the different parts of maintenance and maintenance development.

JERNBRO MAINTENANCE WAY – IN 5 EASY STEPS

0. SITUATION ASSESSMENT

We start with a situation assessment to identify where the organisation is within a number of different areas. The result is illustrated by colouring each block in the pyramid red, yellow or green.

1. DEFINE GOALS

In the next step we identify the desired position of the organisation in order to be able to reach the specified goals. The purpose is to define goals you then can link to, for example achieve a certain level of reliability and minimize breakdowns. With the help of the pyramid, you see which areas need improvement to reach the goals.

2. IMPLEMENTATION

Here you start to implement a number of small improvements in the blocks of the pyramid. Each activity is linked to the blocks. There is a problem description and an action plan. This step can be seen as a master plan, where you get a visual picture of the overall level of the priority areas you need to work with to develop your maintenance activities.

3. FOLLOW UP

This step is about continuous follow up – that you follow the master plan and actually do those things agreed on. It is important to work methodically even if you don’t see results immediately. If you follow the plan, you can be sure to reach results.

4. MEASUREMENT

Now follow up and check that the actions have produced results. You can see how the pyramid begins to improve. Red blocks become yellow and some yellow blocks become green. You can also be sure that costs and operational reliability will improve in the long term.

“Jernbro has presented 300 improvement suggestions and we at Husqvarna have chosen to implement the majority of these. This is well in line with the high focus we have on continuous improvements!”

Magnus Wohlin, Husqvarna who got help with maintenance development and an agreement for maintenance resources.