Specially adapted lifting

equipment and lifting devices

We offer a complete concept within lifting equipment and lifting devices that have the task of lifting and lowering loads and machines of various kinds. We help the industrial sector throughout Sweden from idea to installation, and ensure that the requirements of the Machinery Directive are met. The work includes design, technical calculations, risk analysis, manufacturing, test load and CE-marking.

- We develop all types of lifting equipment and lifting devices that need to be specially adapted for your purposes. This applies to everything from simple to complex solutions with, for example, magnetic and vacuum lifts

- We also provide standard types of lifting equipment, such as traverses, slewing cranes and hoists

- We also take care of service and maintenance of all lifting equipment and machines

In connection with delivery, all required documentation is submitted.

But if necessary, we also offer training in how to handle the new lifting facility.

Load testing

and CE-marking

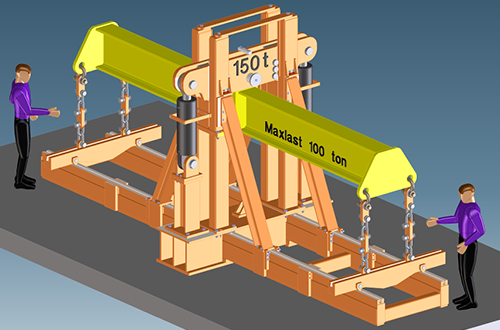

Before we deliver new devices, we perform test loading in accordance with the Machinery Directive. This means, among other things, that the unit must be able to lift 50% more than the nominal load.

Our test rig can lift with high precision up to 150 tons and a maximum pressure of 50 tons.

If the test load is approved, we CE-mark the device, which shows that it’s approved for its purpose and meets all health and safety requirements. All details and components are traceable.

Ali Eshgi and Magnus Andersson-Lindwall

Ali Eshgi and Magnus Andersson-Lindwall

next to Jernbro’s test rig