When Siemens Energy AB was about to build new lifting equipment for their test rigs for gas turbines, Thomas Christiansen at Siemens contacted Ali Eshgi, Master of Science in Engineering at Jernbro. Thomas wanted help with the lifting machines function and design.

Turbines in different sizes are tested at Siemens test rigs

Mainly new turbines tested at Siemens’ four test rigs in Finspång, but also those that have been back home for repairs etc. Thomas and his colleagues ensure that the right effect is achieved in relation to the machine type, that the vibration performance and rotor dynamics are good and that it looks good in terms of emissions. Everything on the turbine is also tested, such as valves and guide rails.

– We are here as a function to test that everything works as it should, before the turbine is sent on to the final assembly. It gets an approval to move on. It’s like starting a new machine for the first time, on which you have to make everything work for a certain period of time.

Between 40-60 units are tested each year at the test rigs. A turbine’s test cycle takes between 7 and 10 days, depending on what kind of machine it is and what’s to be tested on the machine. The turbines are powered by natural gas and are used to generate power or compressor operation.

Thomas works as an operator at all four rigs. In total, they are 14 people. Two of them are hired on full-time from Jernbro, since about 9 years.

Three lifting devices are built for Trifsrigg 1 and 2

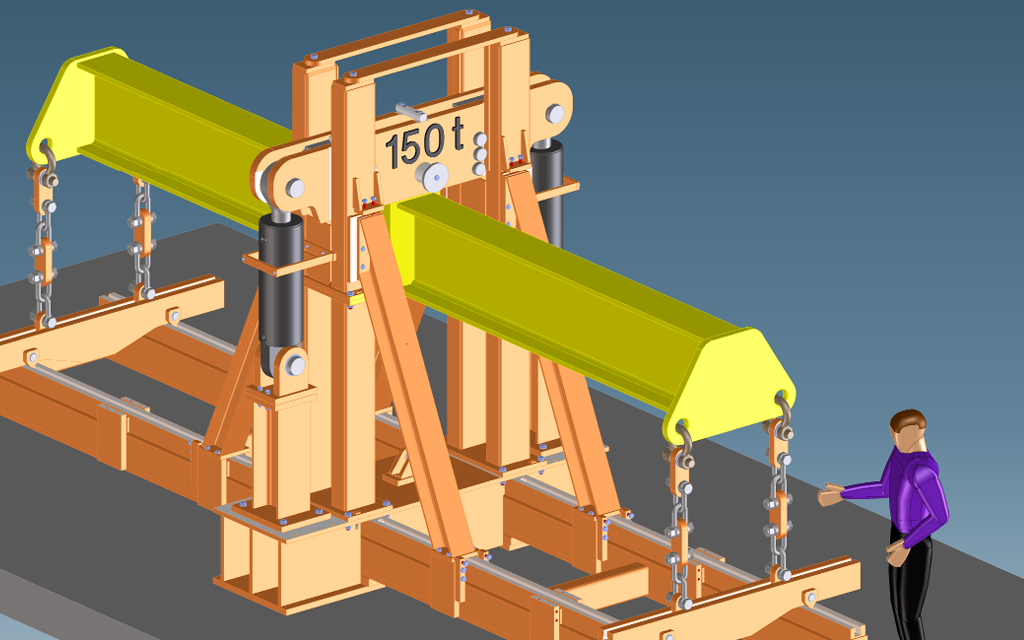

Ali and his colleagues at Jernbro have built three lifting devices for Siemens test rigs; one to lift the compressor turbine, another for both the compressor turbine and the outlet housing and a third larger one to lift the entire large test adapter. Jernbro’s lifting machines are used on 2 of the 4 rigs; Trifsrigg 1 and Trifsrigg 2.

Ali and his colleagues at Jernbro have built three lifting devices for Siemens test rigs; one to lift the compressor turbine, another for both the compressor turbine and the outlet housing and a third larger one to lift the entire large test adapter. Jernbro’s lifting machines are used on 2 of the 4 rigs; Trifsrigg 1 and Trifsrigg 2.

The task of the two smaller lifting devices is to provide Trifsrigg 1 and 2 with turbines to be tested. The lifting machines are motor-controlled to be able to balance the weight. This means that the lift is always stable, which makes it easier to aim and steer the load. In this way, it also provides a much safer lift. Turbines and various machines that are tested run between 17 and 25 tons. The turbine consists of 5,000 components and is 1.5–3 m in diameter and 5–6 m long.

Lifting device with power to lift 80 tons

When all connections are fitted and the machine is completed, the large lifting machine is used. It can lift up to 80 tons and can thus drive the entire test adapter, which weighs between 40 and 50 tons, into Trifsrigg 1. The lifting device is motor-controlled and gives the test adapter its own balance point so everything can be lifted straight and even.

– For these heavy machines, that are to be aimed with such small margins, the lifting devices work really well. These machines, that Ali has built, have helped us a lot, Thomas says.

Every year, Jernbro is on site to carry out condition checks of the lifting devices. Jernbro, and especially Ali, is also helpful with fall protection at the test facilities as well as other lifting machines and sweeps for various steps. Jernbro also takes care of the maintenance of Siemens traverses and cranes.

– We get professional help from Jernbro and they are very service-friendly. The help we get has a high level of knowledge.