Jernbro in Avesta has contributed with the manufacture of complex details to CorPower Ocean’s first full-scale product CorPower C4. It is a buoy that is 19 meters high and has a diameter of 9 meters, which will generate energy from sea waves.

− Jernbro have helped us with fast service several times during the project. The team has really supported us 100%. I understand that Jernbro also has found it fun to work with us, with our fast reactions and challenging things to manufacture, says Thomas Lindahl, Senior Purchasing and Quality Engineer at CorPower Ocean.

CorPower Ocean came into contact with Jernbro when they quickly needed to manufacture new components for their test facility for wave power testing in Västberga (which by the way is the world’s largest). The quick implmentations were handled excellently and have been of great importance to CorPower’s schedule. This led to an expansion of the collaboration, as CorPower Ocean needs creative suppliers who can handle short lead times for complex components at reasonable costs.

− The buoy generates energy as it moves up and down with the waves. It is thus the energy stored in the waves that is converted into electricity for the power supply of businesses and households near coastal areas, Thomas explains.

It has really been a different project, for Jernbro, and they think it’s fantastic to somehow have been able to contribute to the green transition. Jernbro were one of the few companies that could solve the task in the short time available.

Everything Jernbro have done has been something they have never done before and sometimes they have received drawings that have been approved almost the same day. It has also been rewarding in that they have been able to talk directly with the designer and have given tips and advice on what you can change to make it easier and cheaper and at the same time with higher quality.

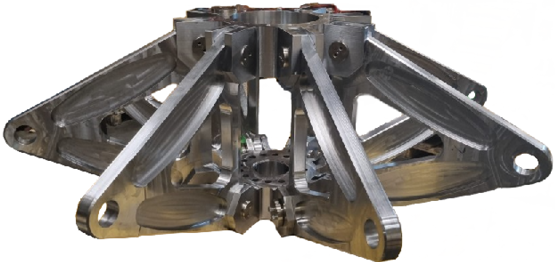

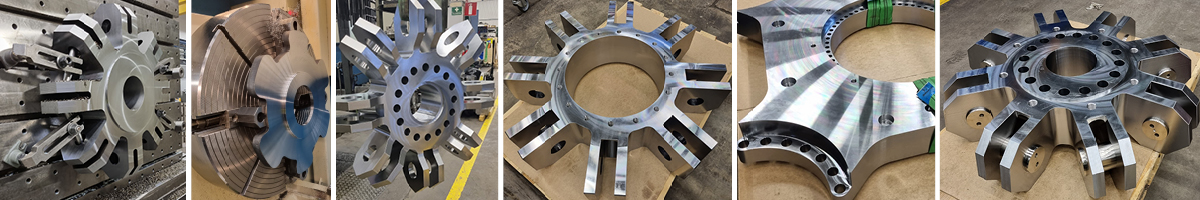

− The picture above shows load-bearing components in high-strength steel. Jernbro has made several of its parts with high tolerance requirements. The processing was carried out with the help of bodywork equipment on the machines. We had an idea of how we would do it and Jernbro realized it in a creative and competent way. Jernbro did not back down from the tough challenge, says Thomas.

Jernbro has been involved in the final phase of the prototype’s full scale, which will be launched in Portugal during the autumn. After that, work begins on developing and manufacturing 3 more buoys of the next generation that will form a mini park. A collection buoy will also be built to be able to transfer energy to the electricity grid on land with minimized energy losses.

For Jernbro, it feels really good that CorPower Ocean has appreciated their availability and that they have met their deadlines. A fun proof that they are happy with their effort is that they have framed a drawing on one of the details Jernbro have made.

− Jernbro has been an important supplier to us and the collaboration has been excellent. Jimmy and his colleagues have been very supportive and constantly helped us with several complex details. Even when we have called on a Friday, they have solved it in the best possible way, Thomas conclude

Read more aboutCorPower Ocean >>

This is how the buoy works >>

Examples of details, manufactured by Jernbro