At HKScan in Linköping, attention was drawn to inefficient heat recovery from the cooling machines due to increased energy costs. Now the system has been rebuilt, re-dimensioned and designed according to its new conditions. The result is a functioning system with an increased lifespan, which also contributes to large energy savings.

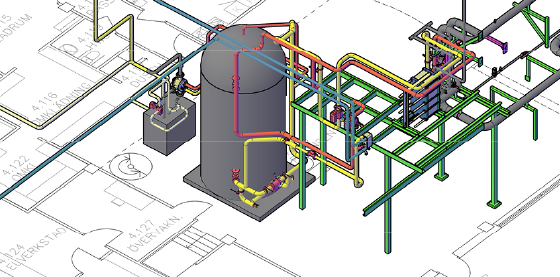

One of HKScan’s heat recovery systems takes care of the emitted heat energy from the cooling machines through a tube boiler heat exchanger, which in turn transfers the energy to an accumulator tank. If necessary, the energy is transferred further for production of hot water. In connection with the increase in energy costs, inaccuracies in the recovery system and that it could be possible to increase the heat recovery, were noticed.

− Initially, Jernbro helped us with pipe adaptations to bring in a circulation pump after we had drained the entire heat recovery system, says Oskar Kollserud, engineer at HKScan in Linköping.

− Initially, Jernbro helped us with pipe adaptations to bring in a circulation pump after we had drained the entire heat recovery system, says Oskar Kollserud, engineer at HKScan in Linköping.

After that, HKScan also had chemists involved for chemical cleaning of the system to removing internal corrosion in the pipe system. However, the efforts did not end up with the desired results. Jernbro was therefore hired to contribute to further investigation. This resulted in a new hot gas heat exchanger being installed to be able to use the heat from the cooling machines. This is to accumulate as much heat as possible in the accumulator tank, in order to be able to preheat the hot water as much as possible.

Before the installation, Jernbro also carried out the demolition of the old pipe system and the repair of holes in the tank, so it could be reused.

After the intervention, the production of materials and the determination of functions as well as the dimensioning of pipes, valves, pumps and heat exchangers were carried out. The dimensioning was preceded by a lot of measurement by HKScan to see which needs there were, how the heat is distributed and how the hot water is used throughout the day

The accumulator tank has been refurbished inside and its volume has been reviewed. Everything around the tank is basically new. Finally, installation was carried out.

− We also have more interesting projects underway together with Jernbro. For example, we are going to change the one steam heat exchanger to make use of more of the energy from our steam condensate, where we have chosen to use a vent condenser. Based on the operation of the machines and the plant, our forecast is that the hot gas heat exchanger together with the new vent condenser will generate up to 3 million kWh ( 3 GWh), Oskar explains.

It is unusual to make such large savings with so few measures. HKScan saves on many parameters, such as energy, effect and flow charge.

− I think that Jernbro’s main strength is the energy department’s competence. I also appreciate that Jernbro offers both comprehensive solutions and smaller individual efforts. With their various skills in projects and maintenance, they can adapt completely to the customer’s needs and their wishes, Oskar concludes.

The accumulator tank (25m³), the hot gas heat exchanger and the heat exchanger that preheats the hot water, as well as associated pipes.