Schlötter needed fast production of the unique transport robots of the Delta lift type. Jernbro took the opportunity to help a new customer so they could deliver on time to their end customer.

Schlötter, which has doubled its sales in the past year, needed to expand its circle of suppliers to keep up with all orders. Torbjörn Eriksson, CEO of Schlötter, contacted Jernbro, who previously had told him about Jernbro’s capacity in construction, manufacturing and assembly.

− We needed a complete supplier with expertise in design, electronics, welding and other technologies and who could undertake larger assignments. It feels stable and secure to have several suppliers to lean on, so we have time to the extent we want, Torbjörn Eriksson explains.

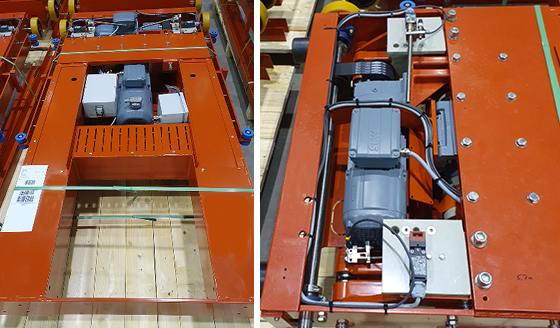

− In our first project together with Schlötter and its subsidiary Galvanoservice, we manufactured and assembled 11 delta lifts of approximately 2 x 1 meters, based on their drawing material. In our work, we used our knowledge in welding, water cutting, project management and construction. There were also a lot of electrical jobs to connect motors, junction boxes, sensors and other electronics. Not to forget is the packaging itself, which we have also manufactured, says Daniel Pascotte, Business Unit Manager East.

− This particular project was very time constrained, but since we are situated in several places and have many different skills, we were able to keep the short schedule of about 2 weeks, so the end customer could get their order on time. The good cooperation and that all components that were to be assembled, arrived on time, contributed as well, Daniel explains.

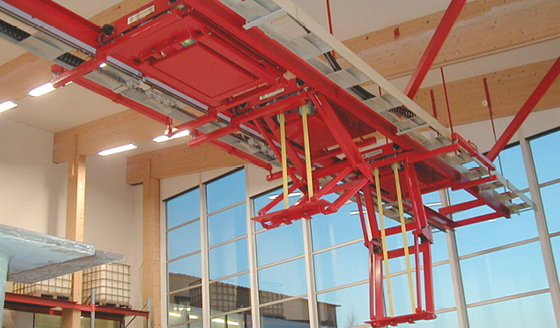

The delta lifts function as lifting trolleys and are installed in the roof of the end customer where they travel around and move goods up and down between different process tanks.

− Since the project with the delta lifts was completed, we have done many manufacturing jobs for Schlötter. Usually we make according to their drawings, but our own designers are happy to suggest improvement suggestions that save time and money. If necessary, we also assist with our own drawings. They are satisfied with that, says Daniel.

An example of another project is lifts with a capacity of one and a half tons. These are installed on the same facility as the delta lifts, but are used for service and maintenance.

− What I appreciate about Jernbro is that they also have designers who can help with drawing materials when we ourselves don’t have time. In addition, they have shown high competence in lifting equipment, test load and CE marking. Jernbro is really a complete supplier with whom we have a good and serious collaboration. That is why more projects have landed on Jernbro from our side. With that, they also learn more about how we work and how our products work, Torbjörn concludes.