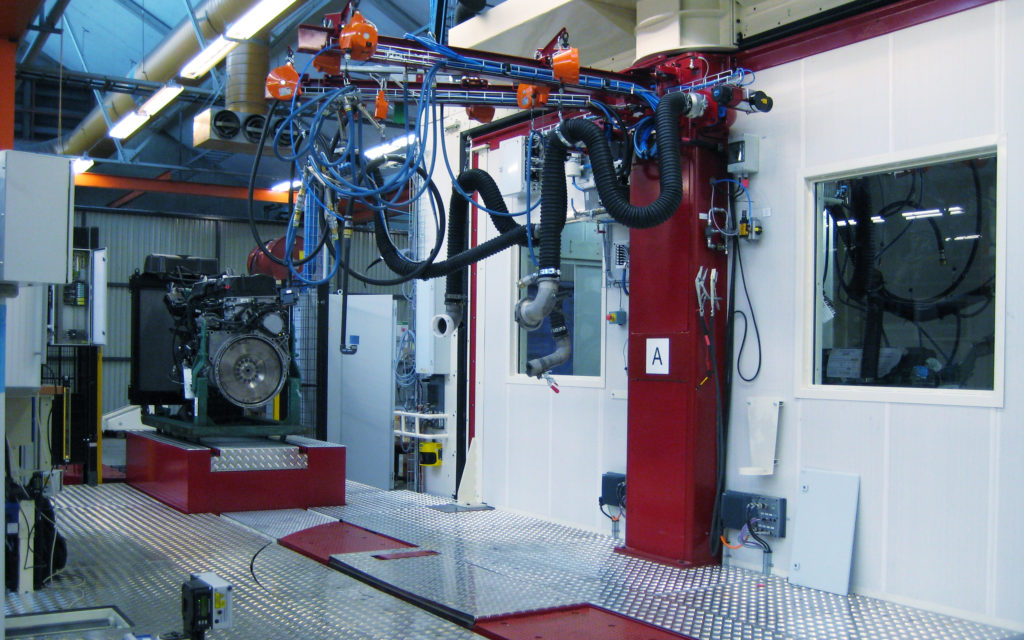

We have won an order of AGV systems from Navistar, which will be used in their production of diesel engines. Navistar is a producer of International® brand commercial trucks, proprietary diesel engines and IC Bus® brand school and commercial buses. The project will run throughout 2021 with an initial delivery of AGVs to the factory in Huntsville, Alabama, USA in February.

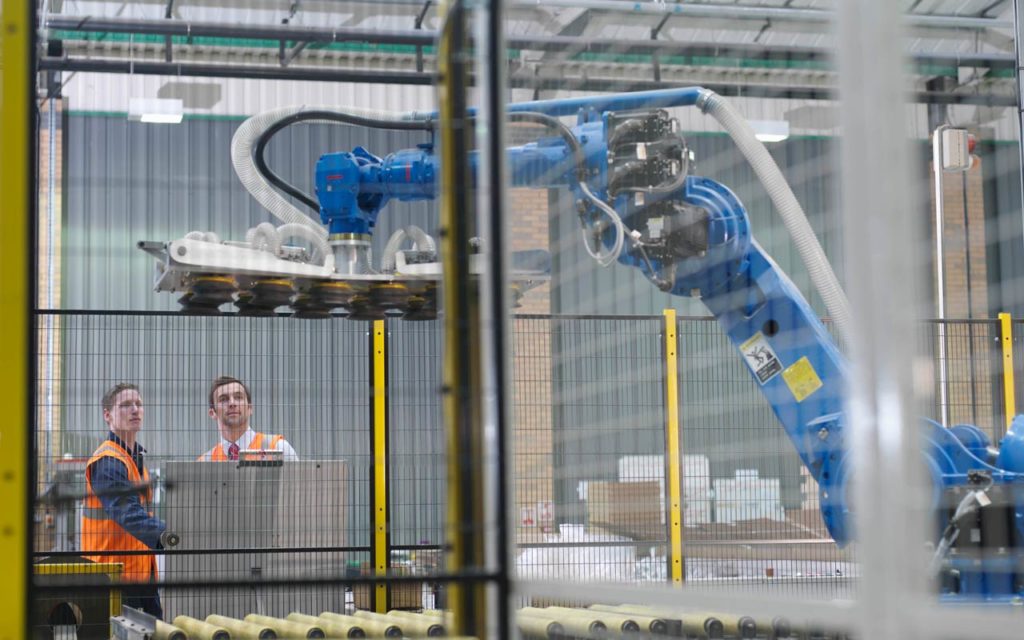

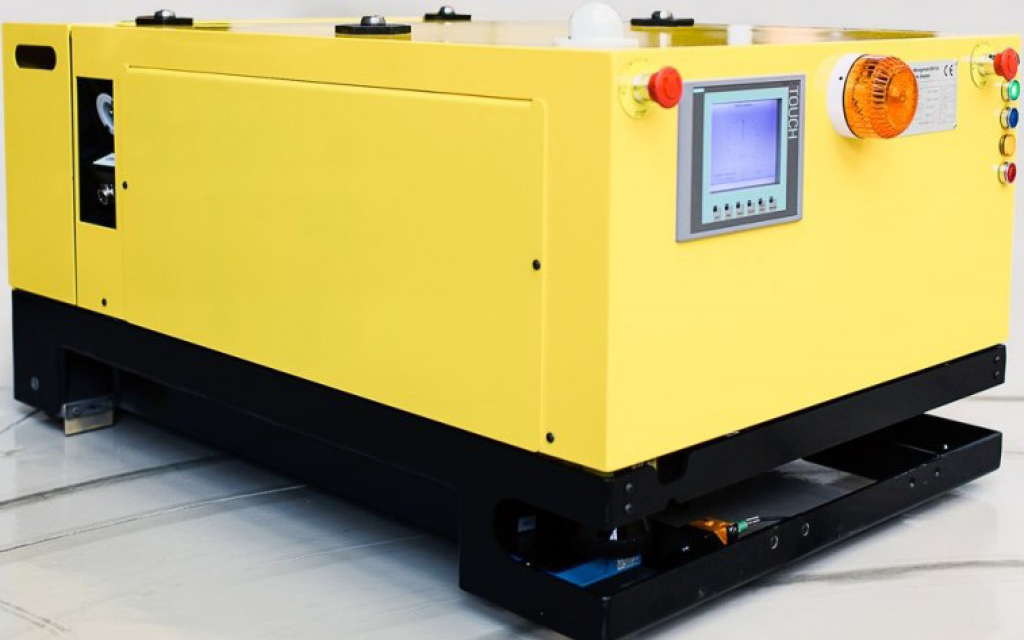

The order includes systems for both assembly lines and production-related logistics. The systems consist of a significant number of AGVs (Automated Guided Vehicles), fixtures and central units for both AGV control and communication with other systems and equipment.

– We’re looking forward to having the overall responsibility in an environment with high demands on accessibility, ergonomics and safety. A major reason for Navistar to choose automation solutions, which are based on AGV concepts instead of fixed installations, was that they were keen to create production arrangements with a high degree of flexibility to be able to meet future requirements. Jernbro’s references from several previous installations with correspondingly high requirements were also of crucial importance, says Pär Knutsson, Sales Manager at Jernbro’s Automation unit.

The deal was signed after extensive investigative work, including evaluation of pilot equipment. Hardware and software are tailored to specific needs defined by Navistar.

– We are proud to have made this deal that contains both a large variety of different AGVs and five different systems. The order demonstrates our strength and competitiveness, concludes Pär Knutsson.