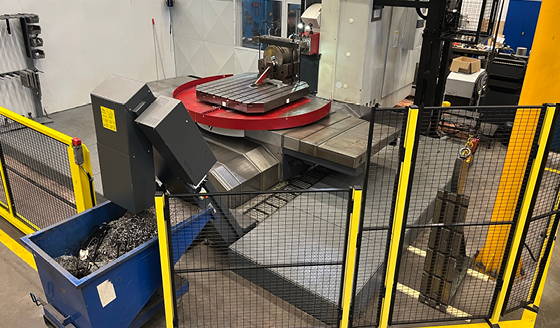

In Avesta, our machining workshop has been expanded with another boring machine. The machine is used for processing complex details. Gearboxes, brake discs and bearing housings and much more are also very suitable.

The investment means an increased capacity, but also a higher precision capability in that the new one can be accessed from four directions on smaller products compared to the existing one, which has access from two directions on small details.

The latter also means that the work becomes easier and smoother for those who handle the machine. Additional ease of use for the operators will also be provided by automatic tool change and installed measuring probe. Among other things, it will help to ensure that the parts get the desired machinings.

The two boring machines will work in parallel with the details that suit each machine best. The new machine can lift workpieces up to 5 tonnes and has an X movement of 2 m and a vertical Y movement of 1.7 m. The older machine can handle workpieces weighing as much as 20 tonnes, X movement of 4 m and Y movement of 2 m.

The installation work went well and most of it was carried out with external help. The electrical work has been carried out by Jernbro though. Now that the last parts have been completed, such as the fence, the cabin, as well as the steel floor that gives the executors optimal working height, the macine has started to work.

The operators have received training on the machine. Since it is a well-known type of machine, as well as software and control systems that the operators feel at home with, learning was smooth.

Several jobs are already planned. For example, gearboxes must be renovated, brake discs must be milled and bearing housings, various axles and keyways must be machined.

In addition to boring, we also offer water cutting, milling and lathing.