Component service

and calibration

Extended lifetime

Repairs and preventive service that maximize the lifespan of your motors, pumps, spindles, and other critical components.

1

Independent expertise

Brand-independent workshops with specialists in electronics, hydraulics, and mechanics – solving problems even when spare parts are hard to find.

2

Reduced downtime

Fast, reliable service from local workshops and field technicians to keep your production running without unnecessary stops.

3

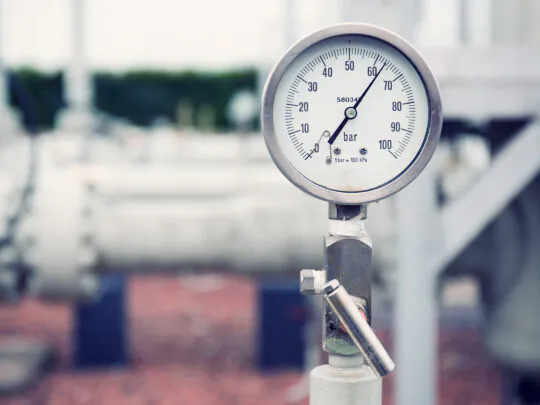

CALIBRATION services

We offer both accredited and traceable calibration, backed by extensive service and repair capabilities to maximize instrument life and reduce cost.

Get Help with Your Components

Need service, repair, or calibration for your components? Tell us about your needs – big or small – and our specialists will get back to you with the right support.

Get Help with Your Components

Need service, repair, or calibration for your components? Tell us about your needs – big or small – and our specialists will get back to you with the right support.