SSAB strengthens operational reliability of hot rolling mill

Jernbro has, in collaboration with main contractor ABB, played a central role in SSAB’s modernization of its hot rolling mill in Borlänge. To future-proof availability, energy efficiency and stable operation, new drive equipment has been installed. This is an important investment for both the region and the green transition.

SSAB’s hot rolling mill is an important part of steel production, but over time the drive system has become outdated and difficult to maintain. To maintain stable production and enable continued high availability, SSAB decided to implement a comprehensive reinvestment.

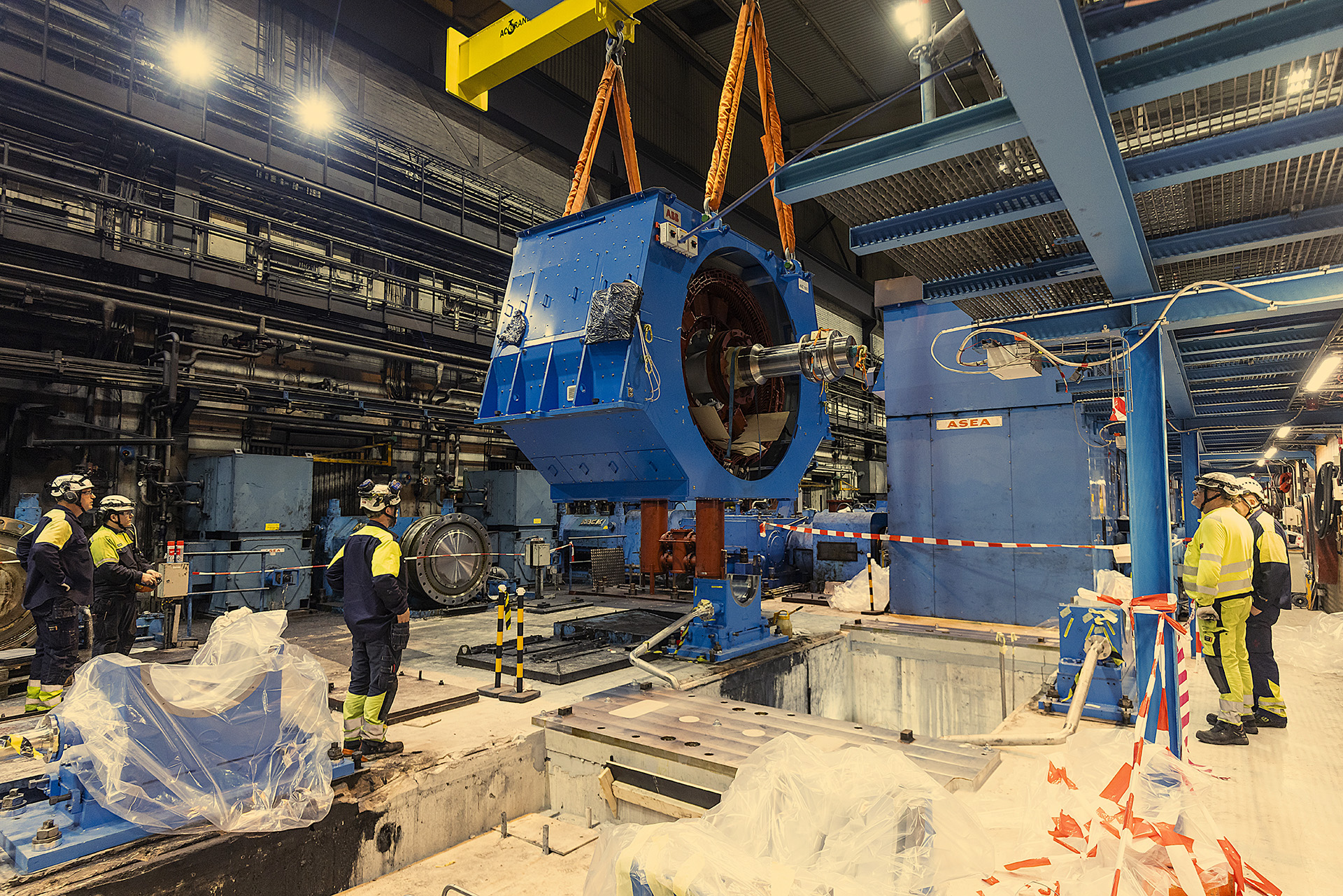

The project includes replacement of six large rolling drive motors with associated converters and transformers in three phases, where the first phase was completed in summer 2025. To enable the installation, a new electrical room was also built.

THE CHALLENGES were many

Tight schedule, large and heavy components, where a main transformer for example weighed 43 tons, as well as requirements for the highest safety when handling high-voltage equipment. Additionally, the installations were carried out in parallel with operations and other maintenance efforts, which required careful planning and coordination between Jernbro, ABB, SSAB and other suppliers.

EXTENSIVE electrical and installation work

Jernbro was responsible for extensive electrical and installation work on behalf of ABB.

- Construction of ducting and cable routes to the new electrical room.

- Installation and setup of transformers and drive systems.

- Installation of large quantities of cable, including high-voltage cables.

- Lifting, planning and assembly of heavy equipment.

- New mounting points and flooring in connection with motor replacements.

Do you need help with electrical and installation?

Benny Egerstad

Group Manager Project and Calculation Electricity

Do you need help with electrical and installation?

Benny Egerstad

Group Manager Project and Calculation Electricity